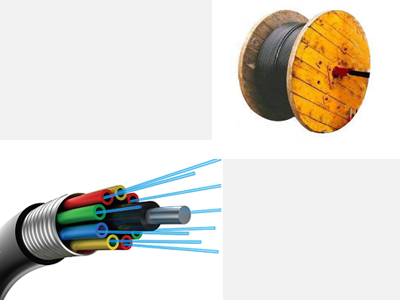

Spiktel dominates to only quality products. Since the adventutre of fiber optics spiktel has led the way with innovative cable technologies that deliver exceptional solutions for our customers. Our manufacturing facilities for our cable products include various designs like ADSS, Indoor , Loose tube , OPGW and various Composite designs. Spiktel is hiring a team of highly experienced engineers who carefully analyze each customer’s application, then customize products to best fit those needs. Spiktel resources are available for on-site training and installation oversight to ensure your cable functions reliably for many years to come. Spiktel used to perform various tests for their manufactured cables like Maximum Installation Load Test, Impact Test, Compression test, Repeated bending Test, Cable Bend Test, Temperature cycling Test, Water Penetration Test etc. to ensure the supply of best product in market.

All-Dielectric Self-Supporting (ADSS) Cables

All-Dielectric Self-Supporting (ADSS) CablesADSS has a long history of successful installations in a variety of challenging climates. This aerial fiber optic cable contains no metallic components nor does it require support elements or earth bonding when installed. This results in improved safety and simplified installations for high and medium voltage transmission line circuits with span lengths from a few hundred feet to several thousand feet.

Indoor Cables

Indoor CablesIndoor cables are manufactured in tight buffered solutions for in-building network installations with strict building code requirements and in high performance applications where connectivity is absolutely essential. Spiktel offers various options such as armored tight buffered, tight buffered indoor and outdoor, sub-unitized premise MicroCore and hybrid fiber/copper.

Loose Tube Cables

Loose Tube CablesLoose tube is a commonly used for aerial lashed and direct bury installations. IN this we offer various constructions like Duct , Unarmored, Armored, Micro cables. The abrasion-resistant sheath material and robust construction make it ideal for conduit pulls between buildings. For those applications requiring a more robust design whereby the cable can withstand harsh chemical exposure or extreme temperatures. Spiktel’s loose tube cable is available in armored and non-armored configurations with various outer jackets to withstand a range of environmental conditions, We have an option to meet your special environmental requirements.

Optical Ground Wire (OPGW)

Optical Ground Wire (OPGW) OPGW runs between high-voltage transmission towers, and optical fibers within the cable are used to transmit data for the purposes of protection, control and/or voice communication. Spiktel is the global leader in OPGW capacity and product diversity and also offers a complete line of attachment hardware for the installation of OPGW, including dead ends, suspensions, splice enclosures and others

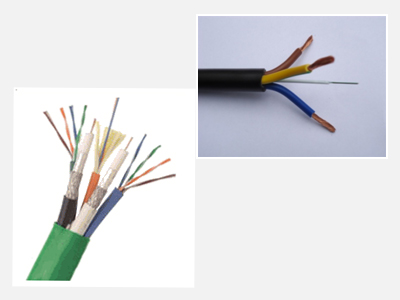

Composite Cables

Composite Cables Spiktel’s specialty fiber optic cables for their customized deigns like Fiber with Power cables and Fiber with data cables etc. We offer a perfect solution in high pressure and high temperature applications such as subsea and refineries. We manufactures umbilical component, high temperature downhole and LSZH sensing cables which are available in non-armored, single-armored, harsh environment and high fiber count/density configurations. All of our cable products are made to order to your specifications. With proven reliability, an exceptional product and industry know-how, spiktel is the right choice for your fiber optic cable needs.